This series assumes you took the

carbs apart, and are trying to figure out how to put them back together again.

If you haven’t taken them apart yet, it’s a good idea to skim through this

first anyway. Address any questions to: xj-owners@micapeak.com,

and we’ll try to talk you through it.

Pictures and text by Dwayne Verhey

The

“Before” picture. Note the arrangement of the starter circuit shaft and levers.

The

“Before” picture. Note the arrangement of the starter circuit shaft and levers.

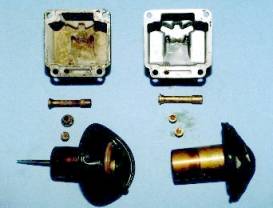

Before and

after cleaning. The parts on the left are as removed. This carburetor was last

cleaned 2 or 3 years ago, and was stored full of gas with stabilizer added for

each winter, and run for 20 minutes every 2 or 3 weeks. Even so, there’s

obviously lots of varnish!

Before and

after cleaning. The parts on the left are as removed. This carburetor was last

cleaned 2 or 3 years ago, and was stored full of gas with stabilizer added for

each winter, and run for 20 minutes every 2 or 3 weeks. Even so, there’s

obviously lots of varnish!

The parts on the right were soaked

in a commercial carburetor cleaner (KleenFlo) overnight. The piston was soaked upright so the rubber

diaphragm was not immersed. Don’t soak any rubber bits, they swell up and soften,

and may be ruined.

All

passages should be thoroughly blown out with compressed air while the parts are

still wet with cleaner. Then they should be rinsed (water or mineral spirits,

depending on the directions of the cleaner) and blown out again.

All

passages should be thoroughly blown out with compressed air while the parts are

still wet with cleaner. Then they should be rinsed (water or mineral spirits,

depending on the directions of the cleaner) and blown out again.

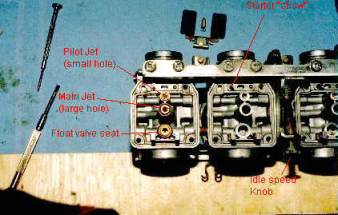

Don’t

forget the starter jet and passage, located in the float bowl. The jet is tiny

(the same size hole as the pilot jet); so don’t be tempted to shove something

down there to open it up! If absolutely necessary to clear a completely plugged

jet, use a bristle from a stiff nylon brush. Then soak it out in cleaner

overnight again.

Don’t

forget the starter jet and passage, located in the float bowl. The jet is tiny

(the same size hole as the pilot jet); so don’t be tempted to shove something

down there to open it up! If absolutely necessary to clear a completely plugged

jet, use a bristle from a stiff nylon brush. Then soak it out in cleaner

overnight again.

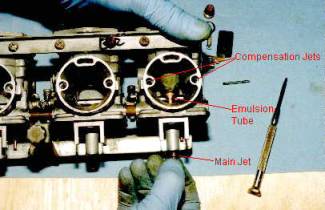

Many

passages are joined. Place a finger over each passage outlet, one at a time, to

ensure they are all clear. The same applies with the emulsion tube, shown here.

Gloves not only keep your hands clean, they protect your hands from the harsh

chemicals, and the possibility of an air embolism when working with compressed

air. Blue nitrile gloves seem to work best.

Many

passages are joined. Place a finger over each passage outlet, one at a time, to

ensure they are all clear. The same applies with the emulsion tube, shown here.

Gloves not only keep your hands clean, they protect your hands from the harsh

chemicals, and the possibility of an air embolism when working with compressed

air. Blue nitrile gloves seem to work best.

(SWMBO wants to know how I managed

to work the camera for this shot. Trade secret ;-)

All parts

should be inspected before re-assembly. This piston and diaphragm are no longer

serviceable. The plastic retainer has cracked and separated. A new one was

obtained from a set of parts carbs from a wreckers.

All parts

should be inspected before re-assembly. This piston and diaphragm are no longer

serviceable. The plastic retainer has cracked and separated. A new one was

obtained from a set of parts carbs from a wreckers.

Note the

fine, fragile, screen attached to the float seat. Careful when blowing this out.

The screen may become dislodged and fly across the room! (Don’t ask me how I

know this…)

Note the

fine, fragile, screen attached to the float seat. Careful when blowing this out.

The screen may become dislodged and fly across the room! (Don’t ask me how I

know this…)

Here’s all

the little fiddly bits laid out and identified. Pay particular attention to the pilot screw bits. There’s a tiny

spring, washer and o-ring that are easily lost, and may not want to come out of

the hole until you start blowing things out with compressed air.

Here’s all

the little fiddly bits laid out and identified. Pay particular attention to the pilot screw bits. There’s a tiny

spring, washer and o-ring that are easily lost, and may not want to come out of

the hole until you start blowing things out with compressed air.

Guess which side of the garage

they’ll land on?

You’re better off gently picking

them out with a dental probe, toothpick, or tiny screwdriver during the

disassembly. They’re much easier to find that way…

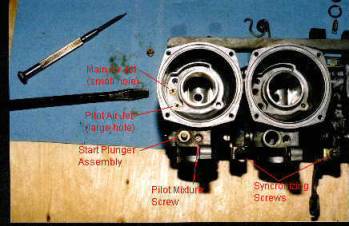

Look at

this picture carefully! At least one of the aftermarket manuals out there mixed

up the air jets in their pictures!

Look at

this picture carefully! At least one of the aftermarket manuals out there mixed

up the air jets in their pictures!

The main air jet has the SMALL

hole, and goes in the center. The pilot air jet has the LARGE hole, and goes to

the engine side.

The empty spot is for the cover

retaining screw, shown later. Also shown here is the synchronizing screw locations

and the pilot mixture screw. Assemble the spring, washer and o-ring to the

mixture screw and gently wind the screw in until it just seats. Back it out 2 ½

turns to start.

Install

the cover over the air jets using the special retaining screw. It has an extra

head to prevent warping the cover when it’s tightened.

Install

the cover over the air jets using the special retaining screw. It has an extra

head to prevent warping the cover when it’s tightened.

Insert the

emulsion tube into the hole through the top of the carburetor. The main jet

retains it with its washer. A little finger pressure on the tube will prevent

it from turning while the jet is tightened. The main jet has the large hole of

the two jets that have heads.

Insert the

emulsion tube into the hole through the top of the carburetor. The main jet

retains it with its washer. A little finger pressure on the tube will prevent

it from turning while the jet is tightened. The main jet has the large hole of

the two jets that have heads.

Don’t forget about the

compensation jets, located on either side of the carb throat. They are easily

identified, having the largest holes of all the jets.

The

starter plunger has a rubber dust seal that can be a bit tricky to reinstall,

but a small screwdriver helps ease the rubber over the flange.

The

starter plunger has a rubber dust seal that can be a bit tricky to reinstall,

but a small screwdriver helps ease the rubber over the flange.

The underbelly

of the rack. Note the pilot jet has the small hole, and no washer.

The underbelly

of the rack. Note the pilot jet has the small hole, and no washer.

Orientation

of the float and needle. The needle has a rubber tip, and so was not soaked

overnight, just rinsed and wiped with a soft clean cloth. Be careful when

handling the floats, so as to avoid bending the thin metal frame.

Orientation

of the float and needle. The needle has a rubber tip, and so was not soaked

overnight, just rinsed and wiped with a soft clean cloth. Be careful when

handling the floats, so as to avoid bending the thin metal frame.

Assemble

the needle, spring, and retainer in the piston with an Allen key. Remember the

spring goes between the needle and retainer! The needle will not sit dead

straight. This is deliberately skewed by a small brass dowel pressed into the

piston. The manufacturer claims atomization of the fuel is more efficient if

the needle is resting against one side of the emulsion tube.

Assemble

the needle, spring, and retainer in the piston with an Allen key. Remember the

spring goes between the needle and retainer! The needle will not sit dead

straight. This is deliberately skewed by a small brass dowel pressed into the

piston. The manufacturer claims atomization of the fuel is more efficient if

the needle is resting against one side of the emulsion tube.

Insert the

piston. It may be necessary to gently guide the needle into the emulsion tube.

Insert the

piston. It may be necessary to gently guide the needle into the emulsion tube.

Carefully

seat the diaphragm all the way around in the groove. There’s an index tab on

the diaphragm that fits into the corresponding notch in the casting. If this is

not carefully seated, an air leak will result in very poor performance.

Carefully

seat the diaphragm all the way around in the groove. There’s an index tab on

the diaphragm that fits into the corresponding notch in the casting. If this is

not carefully seated, an air leak will result in very poor performance.

Don’t forget to put the big spring

in the centre of the piston before reinstalling the domed cover. The flattened

side of the cover goes towards the air box end of the carb.

Reassemble the start plunger

actuating shaft and arms.

An easy

way to set the float heights. The bowls are installed with one screw each so they

can be easily removed and adjusted. The bank is gently clamped in the Workmate

and leveled, leaving the bowls accessible. This way, the level can be adjusted

without having to repeatedly install and remove the carbs from the bike. See

the XJ CD for a complete description of the procedure.

An easy

way to set the float heights. The bowls are installed with one screw each so they

can be easily removed and adjusted. The bank is gently clamped in the Workmate

and leveled, leaving the bowls accessible. This way, the level can be adjusted

without having to repeatedly install and remove the carbs from the bike. See

the XJ CD for a complete description of the procedure.